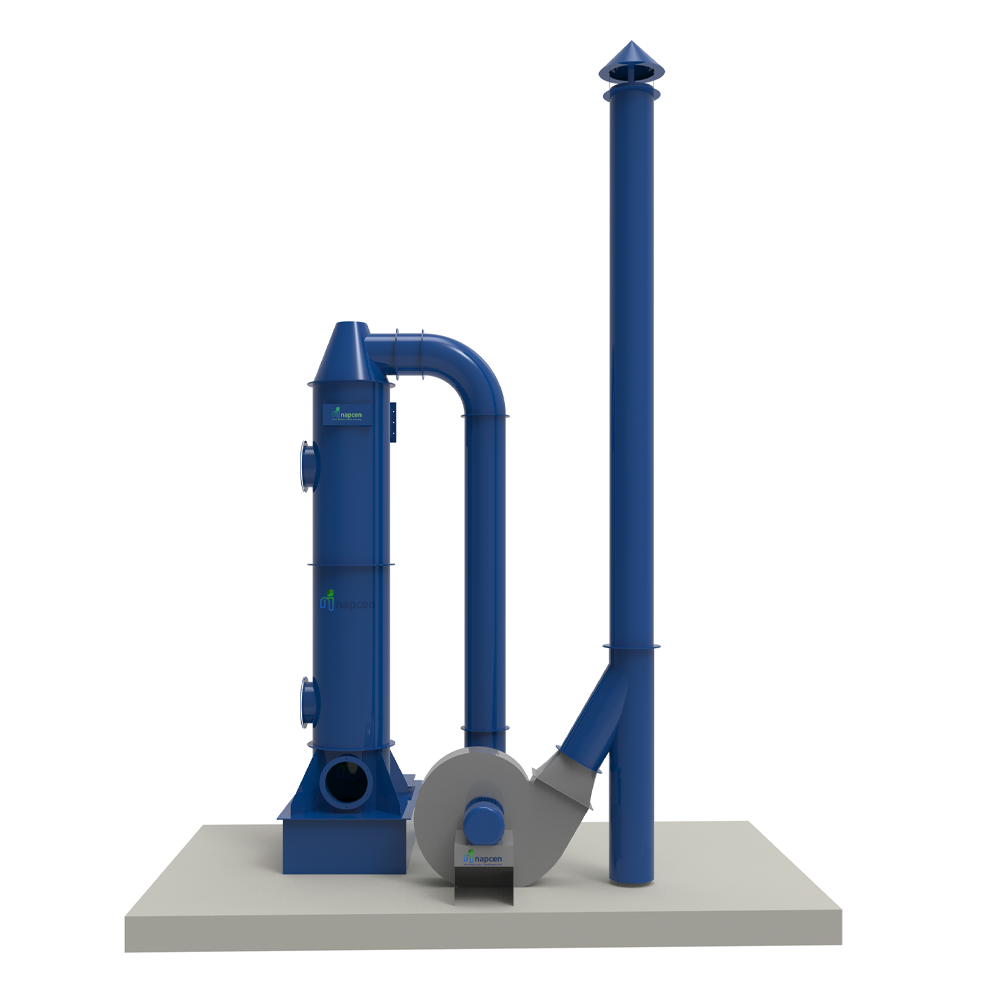

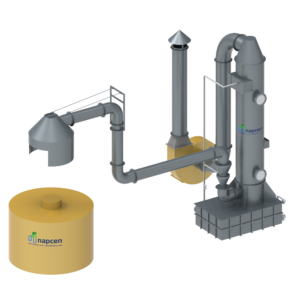

Packed Bed Scrubber

The packed bed scrubber, commonly used in industrial applications, is also referred to as a packed tower scrubber or packed column scrubber. It is designed to remove gaseous pollutants from airflows. When expertly designed and constructed by experienced air pollution engineers, these scrubbers effectively capture and neutralize hazardous and toxic gases from air streams, ensuring the emission of clean air into the atmosphere.

Product Description

Packed Bed Scrubber

Basic description of how a Packed bed wet scrubber works:

The packed tower operates by allowing pollutant-laden gases to enter at the bottom and flow upward, coming into contact with the scrubbing liquid cascading down through the packed column. As the gas ascends, the pollutant concentration diminishes, ensuring a continuous supply of fresh solvent for effective contaminant removal. Subsequently, any remaining moisture droplets in the purified gas stream are eliminated by a mist eliminator. The scrub liquid collected from the eliminator is stored in an integrated reservoir and recirculated back to the tower. To maintain optimal performance, makeup liquid is consistently introduced, and reagent is selectively dosed using a pH monitor-controlled dosing pump.

Packed bed scrubbers can be classified based on their orientation as either vertical or horizontal configurations. Here are some details about each classification:

Vertical Packed Bed Scrubbers:

– In vertical packed bed scrubbers, the gas stream flows vertically upwards or downwards through a column filled with packing material.

– The packing material provides a large surface area for contact between the gas and the scrubbing liquid, promoting efficient mass transfer and pollutant removal.

– Vertical packed bed scrubbers are commonly used when space is limited, as they have a smaller footprint compared to horizontal scrubbers.

– These scrubbers are suitable for applications where the gas flow rate is relatively low and the removal efficiency requirements are high.

Horizontal Packed Bed Scrubbers:

– In horizontal packed bed scrubbers, the gas stream flows horizontally through a vessel filled with packing material.

– The packing material in horizontal scrubbers is arranged in a way that allows for efficient contact between the gas and the scrubbing liquid.

– Horizontal packed bed scrubbers are often used in applications where the gas flow rate is high and where space is not a limiting factor.

– These scrubbers are suitable for treating gas streams with high particulate matter content or for applications where the gas needs to be cooled before entering the scrubber.

Both vertical and horizontal packed bed scrubbers have their own advantages and limitations, and the selection of the appropriate configuration depends on the specific requirements of the application.

key features and benefits of packed bed scrubbers include:

Features:

1. Packed bed of inert material (such as plastic, ceramic, or metal) provides a large surface area for gas-liquid contact and pollutant absorption.

2. Counter-current flow design allows for efficient pollutant removal and high removal efficiencies.

3. Versatile design can handle a wide range of gas flow rates and pollutant concentrations.

4. Can be designed with multiple stages for enhanced pollutant removal.

5. Can be customized with various packing materials and liquid spray systems to suit specific application requirements.

Benefits:

1. High removal efficiencies for a wide range of pollutants, including particulate matter, acid gases, and volatile organic compounds (VOCs).

2. Compact design saves space and can be easily integrated into existing industrial processes.

3. Low pressure drop results in energy savings and reduced operating costs.

4. Easy maintenance and operation with minimal downtime.

5. Environmentally friendly solution for air pollution control and compliance with regulatory standards.

Overall, packed bed scrubbers are a reliable and effective solution for gas cleaning and pollutant removal in various industrial applications, offering high removal efficiencies, versatility, and cost-effective operation.