- Address: Villianur, Puducherry-605110, India

- Email: sales@napcen.com

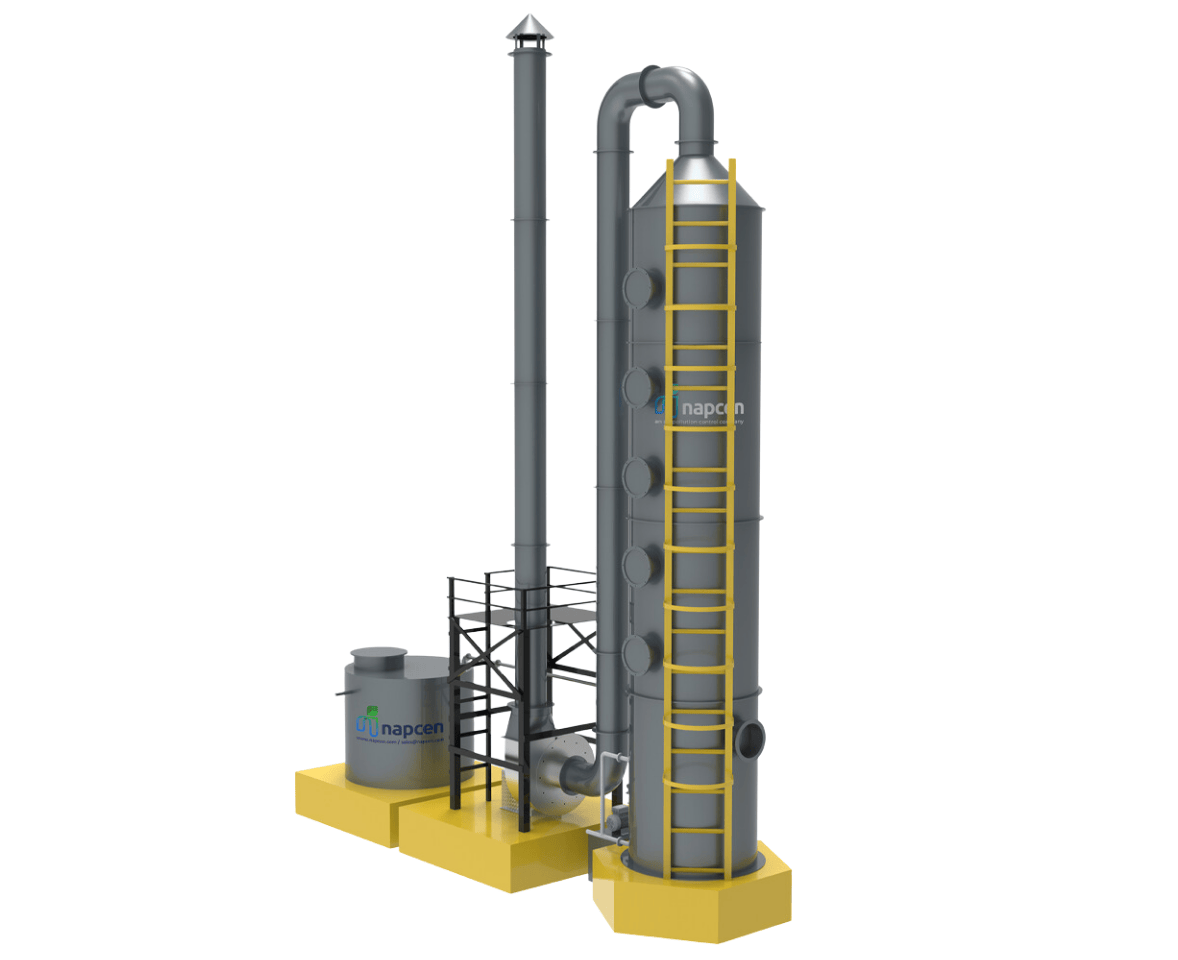

Wet Scrubbers

Dry Scrubbers

Bag House Dust Collectors

Acid Fume Scrubber

Downdraft Tables

Cartride Dust Collector

Grossing Station

Laser / Plasma Fume Extractor

Welcome to NAPCEN

NAPCEN specializes in industrial air filtration and pollution control systems designed to remove dust, fumes, corrosive gases, toxic vapors, oil mist, odors, and other airborne pollutants. Our air pollution control solutions protect people from harmful emissions and improve indoor air quality by effectively eliminating contaminants and unpleasant odors.

Industrial Wet Scrubbers, Dust Collectors & Air Pollution Control Equipment in India

NAPCEN is a trusted name in India for advanced air pollution control solutions. We design, manufacture, and supply a comprehensive range of high-performance equipment, including industrial dust collectors, fume extraction systems, wet scrubbers, dry scrubbers, grossing stations, fume hoods, industrial blowers, heat exchangers, PP FRP scrubbers, and FRP lining services. Our expertise also extends to ventilation systems, ducting, and indoor air pollution control solutions, ensuring cleaner and safer work environments.

Industrial Applications

Testimonial

FAQ’s

-

What is an industrial wet scrubber used for?An industrial wet scrubber is used to remove harmful gases, chemical fumes, and particulate matter from factory exhaust before it’s released into the atmosphere. It ensures clean emissions and complies with air pollution control standards.

-

How do industrial wet scrubbers work?Industrial wet scrubbers work by passing contaminated air or gas through a scrubbing liquid (usually water or a chemical solution). This process absorbs or neutralizes the chemical fumes and dust particles, making the exhaust safe for release.

-

How do you maintain an industrial wet scrubber?Regular maintenance involves checking and cleaning spray nozzles, monitoring liquid levels and pH, inspecting pumps and fans, and ensuring that buildup of particulates or sludge is removed to maintain peak efficiency.

-

Which is the best wet scrubber for factory exhaust?The best wet scrubber for factory exhaust depends on the type of emissions. For chemical fumes, a low-maintenance industrial wet scrubber with corrosion-resistant materials is ideal. Custom-built gas scrubbers offer better efficiency for specific industries.

Our Blogs

How Wet Scrubbers Improve Industrial Air Quality: A Comprehensive Guide

How to Choose the Right Dust Collector for Your Industrial Needs

Successful Implementation of Downdraft Tables in Metal Fabrication

Our Awesome Customer

- +91-7904469219Mon-Satur, 9am until 6pm

- sales@napcen.comWe reply within 24 hours

- No1. North Street, SMV Puram

Villianur, Puducherry-605110, India.